What sets Tower Press apart? EVERYTHING!

Stacked Pressure Rollers

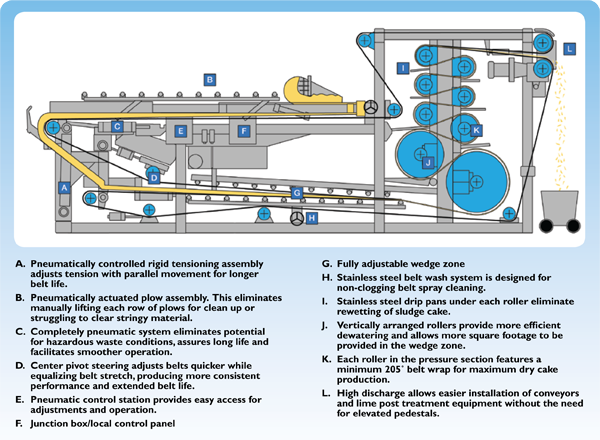

The improved design begins with the vertical arrangement of the rolls. This enables every pressure roll to have a minimum of 205˚ belt wrap, which maximizes time under pressure and guarantees high cake solids.

Individual Drain Pans

This vertical arrangement allows every drop of water removed by the belts to cascade through a series of stainless steel drip pans positioned under each roller, which eliminates the rewetting of any sludge cake between the belts.

Elevated Discharge

The Tower press features an elevated discharge that's more than 6 feet from the base of the press frame making it easier to allow for conveyors or auxiliary equipment.

Center Pivot Tracking

Pneumatic Operation

Our pneumatic belt tensioning maintains consistent and even tension on the belt at all times for smooth operation and longer belt life.

One Piece Bearings

The Tower Press utilizes a one-piece pillow block housing with a gasketed end cap and self-aligning double row spherical bearings. All bearings have a quadruple lip seal.

Available Sizes

The Tower Press and Regent Models are manufactured in 0.7, 1.2, 1.7 and 2.2 meter belt widths.

How it works is innovative.

How it performs is amazing.

Over the years the Tower Press has evolved in direct response to operator suggestions which has made it a better and easier to operate and maintain dewatering system.

- The Tower Press "hands-off" design reduces manpower hours and therefore overall operating costs.

- The entire dewatering process can be observed from ground level, reducing plant design and construction costs.

- Doctor blades and plows are pneumatically actuated for easier operation and clean up. Only the Tower Press and Regent Models offer this exclusive feature.

- Center pivot tracking rolls eliminate one-sided belt stretch and deliver smoother and quicker response to belt misalignment. This provides longer belt life and more consistent performance.

- Rigid tensioning assembly adjusts belt tensions with parallel movement.

- Optional filtrate recycle feature eliminates the need to utilize outside water sources for belt cleaning during operation.