Granular activated carbon (GAC) is a critical media used in water treatment, air purification, and industrial filtration. Its porous structure enables it to adsorb a wide range of contaminants, including volatile organic compounds, chemicals, and dissolved organics. Although it is highly effective, GAC is not a consumable that lasts forever. Over time, its pores fill with impurities and adsorption capacity declines. At that point, facilities have a choice: dispose of the spent carbon or recover it through granular activated carbon reactivation.

Understanding the Lifecycle of GAC

Initial Installation

Virgin carbon is placed into treatment vessels or filter units.

Adsorption Phase

As wastewater or process streams pass through, contaminants are trapped inside the carbon’s pores.

Breakthrough

Once the carbon becomes saturated, contaminant removal drops and performance declines.

Reactivation or Replacement

Spent carbon can either be replaced with virgin material or sent for thermal reactivation.

Reactivation renews the carbon for reuse, allowing multiple cycles of service and significantly lowering total lifetime cost.

What is Granular Activated Carbon Reactivation?

Granular activated carbon reactivation is a high-temperature process designed to remove accumulated pollutants from saturated carbon and restore its adsorption capacity. Spent GAC is heated in a furnace or kiln to temperatures reaching 1,700°F in a controlled, oxygen-limited environment. This process thermally decomposes the adsorbed compounds and reopens the carbon’s pore structure.

The reactivated carbon can then be redeployed in the field, usually at a cost substantially lower than virgin carbon while still meeting performance requirements.

Benefits of Reactivation

Choosing to reactivate rather than replace offers several key advantages:

Cost Efficiency

Reactivated GAC typically costs 30–40% less than the purchase of virgin carbon.

Waste Reduction

Less spent carbon is landfilled, which reduces disposal liability.

Sustainability

Reactivation supports circular use of carbon resources and decreases demand for new raw material.

Regulatory Compliance

When handled by qualified providers, reactivation supports compliance with EPA and RCRA disposal guidelines.

Pelton Environmental’s Carbon Reactivation Services

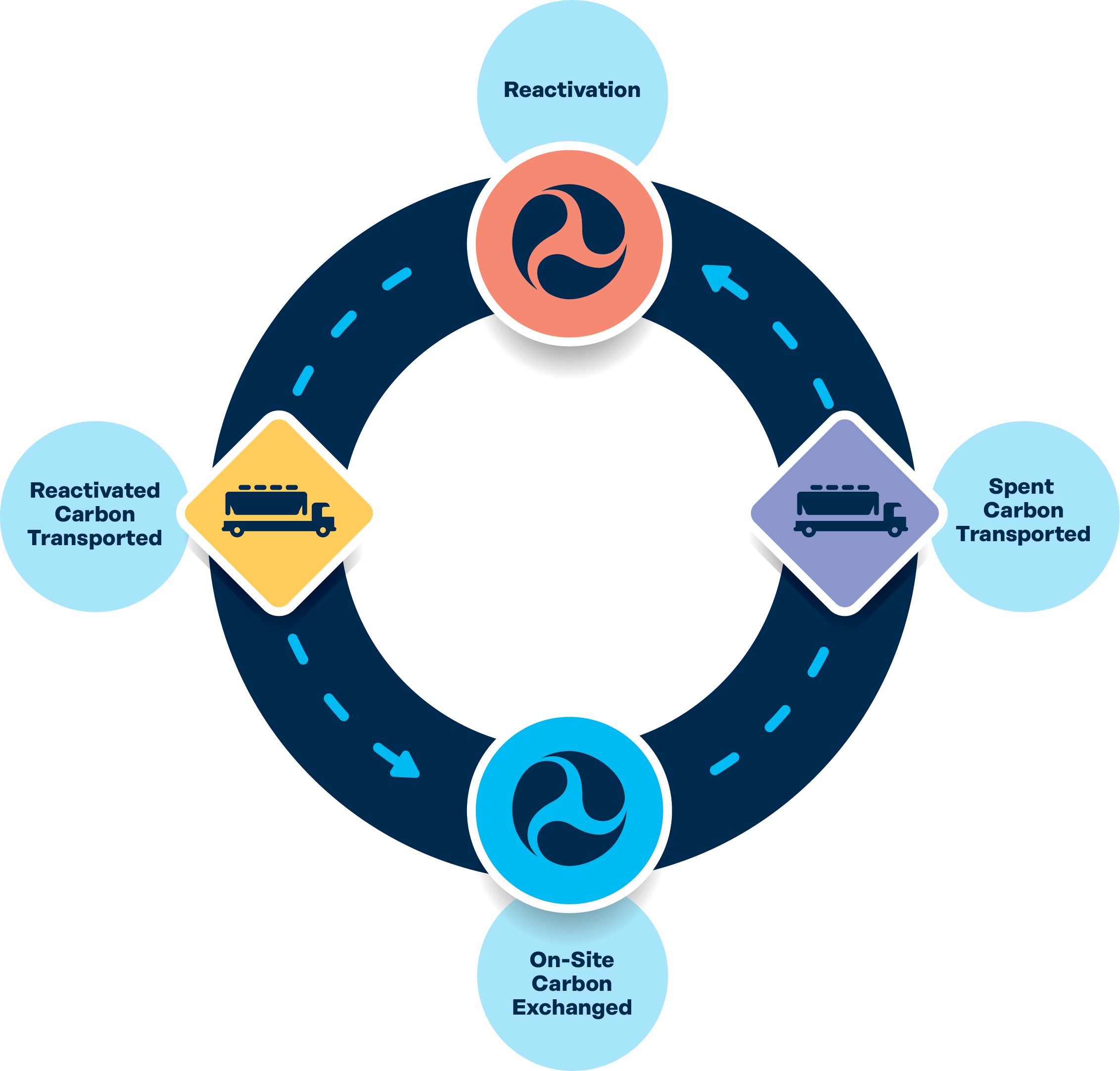

Pelton Environmental delivers turnkey solutions that manage every stage of the carbon lifecycle. Services are suited to municipal, industrial, and remediation applications, and include:

- Spent Carbon PIckup and Transport - Safe removal from site with proper documentation.

- Thermal Reactivation - Processing of spent carbon to restore adsorption capacity.

- Carbon Exchange Services - Swap-out programs where spent carbon is exchanged for pre-reactivated media.

- Industrial Filtration Support - Engineering assistance and troubleshooting of GAC systems to optimize runtime and performance.

Ready to Dive Deeper Into Carbon Reactivation?

Schedule a Lunch & Learn with Us

Want to bring this knowledge directly to your team? Let us host a free, customized Lunch & Learn where we’ll:

- Walk through the full GAC lifecycle, from virgin carbon to reactivation

- Highlight real-world cost, performance, and sustainability gains

- Answer your site-specific questions and troubleshoot your media strategies

Get in touch now to request your session and empower your team with carbon reactivation expertise.

By working with an experienced provider, clients maintain operational uptime while reducing total media-related expenses.

Selecting a Reactivation Partner

Not all reactivation processes are equal. When evaluating a supplier, it is important to vet:

Processing Capacity

To determine if your volume requirements can be met.

Quality Assurance

Quality assurance testing for iodine number, moisture content, and adsorption performance.

Regulatory Experience

Regulatory experience with handling spent media profiles and manifests.

Logistics Capabilities

Logistics capabilities for transporting, exchanging, and reinstalling GAC on a scheduled basis.

Pelton Environmental has the technical infrastructure and expertise required to support each phase of the granular activated carbon lifecycle from installation through reactivation and redeployment.

Have Questions About Carbon Reactivation?

The team at Pelton Environmental is happy to answer any questions you have. Please contact us using the button below.